Quarry Dust

Quarry dust is often a fine layer of dust that is left on a natural stone's surface during quarrying and processing.

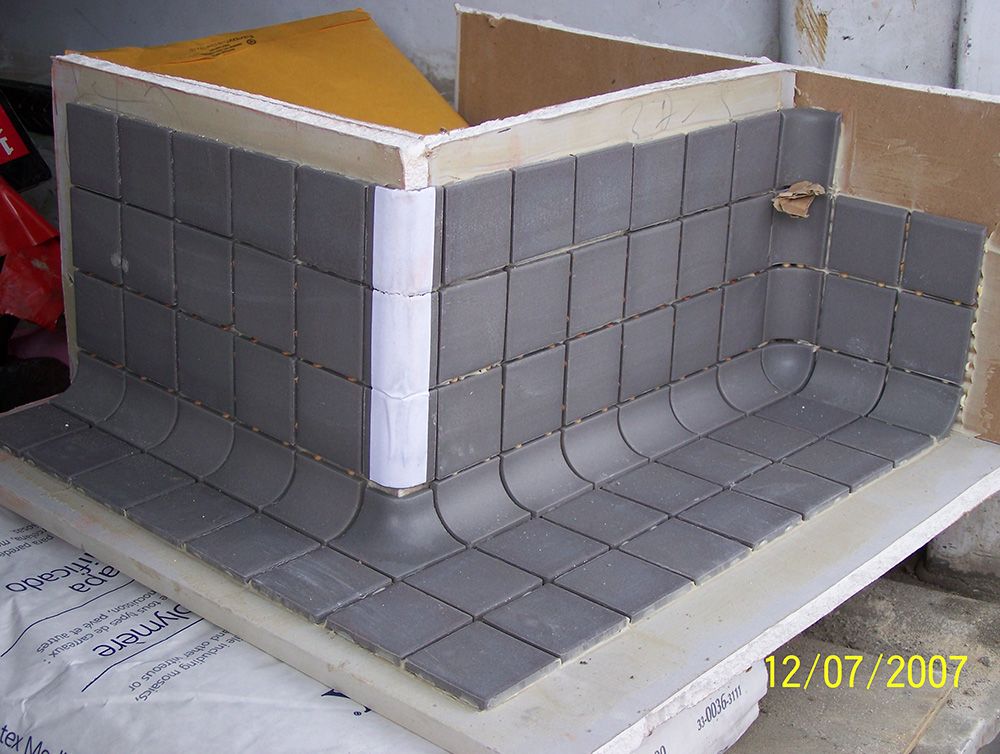

Quarry dust is a layer of material that is left on a natural stone's surface during quarrying and processing. Sometimes it is a fine layer that is barely detectable. Other times, it can be a thick layer that is embedded into the pores (as shown in the photo) that can be a disaster for adhering the stone correctly if not cleaned properly. And it is not just the tiles backside that is important as a layer of dust on the tiles surface can cause havoc when grouting takes place.

Most proper installation methods and techniques call for cleaning the tile’s backside before it is installed. This step can be the difference between project failure or success. Make sure the tile’s backsides are cleaned properly before installation by wiping them with a damp sponge until all dust is removed. The tiles can be installed when they are damp dry but not saturated so care must be taken by not allowing a lot of moisture on the tile before applying the adhesive mortar.

While quarry dust is specifically related to natural stone products, manufactured tiles can also come with a layer of manufacturing dust that also needs to be cleaned. One type of manufacturing biproduct is known as engobe which is often a white material left on a tile backside. While usually not a deterrent to proper adhesion, it is still best to wipe down all tile backsides with a clean damp sponge before installing.

We offer onsite quality control services which can often be the difference between how a project performs and whether a tile is being cleaned and installed correctly or not. Whenever there is concern regarding the proper adhesion of adhesive mortars to a tile, we can oversee and have the tile and installation products tested for compatibility and bond strength beforehand to show any potential issues of concern that should be corrected.